Helping woodworkers online for over 20 years

Types of Wood

| The materials for most projects will fall into three categories: softwood, hardwood and manufactured panels such as plywood.

What you use for any given project depends on various factors: strength, hardness, grain characteristics, cost, stability, weight, color, durability and availability. Usually beginning woodworkers start out with a softwood such as pine. It's soft and easy to work so you don't need expensive tools to get good results. It is readily available at local lumberyards and home centers. It has it's limitations in furniture making, it is a soft wood and will damage easily. Softwood Lumber Pine

and most other softwoods will absorb and lose moisture more than

hardwoods so are not as stable. Purchase the lumber at least two weeks

before starting your project and keep it indoors. Place stickers (small

pieces of scrap wood) between the boards to permit good air circulation

around each piece of stock. This will allow the wood to reach an

equilibrium with the indoor environment which reduces the likelihood of

dramatic wood movement after a project is complete. You will find that softwoods are sold in standard thickness and widths, for example a 1 X 4 will be 3/4" thick and 3 1/2" wide similar to construction materials. The material will usually be priced per lineal foot and the price will increase accordingly for the wider boards. Panels made from strips glued together and sold as shelving are also available, these range from 12 to 24 inches wide and 2 to 8 feet in length. Softwood 101 - Detailed information on the characteristcs and properties of softwood trees. Hardwood Lumber At speciality stores the thickness of hardwood lumber is specified in quarters of an inch, measured when the wood is in a rough state. The thinnest stock is 4/4, representing 1 in., and the thickest usually available is 16/4, representing 4 in. Rather than being milled to specified dimensions, like pine, hardwoods are sold in random widths and lengths. Hardwoods are sold by the board foot, which is defined as a square foot of rough lumber that is 1 in. thick. If a board is thicker than 1 in., the dealer multiplies the square footage by the thickness to arrive at the sale price. An 8/4 board will therefore cost twice as much as a 4/4 board of the same size. Working with hardwoods is quite different from working with pine, you cannot drive a screw through hardwood lumber without first boring a pilot hole. Cutting and planing hardwoods requires extremely sharp tools. Oak

and ash, are known as open-grain woods. These species have alternating

areas of relatively porous and dense wood, when stained the open-grain

areas absorb the color readily while the harder areas are more

resistant. This accentuates the grain patterns, creating a dramatic

effect. Hardwood 101 - Detailed information on the characteristis and properties of hardwood trees. Plywood and Manufactured Sheets You will likely be working with either plywood, consisting of an uneven number of alternating layers of wood, or a type of manufactured sheet. Plywood

and manufactured sheets often come in thicknesses that actually measure

thinner than standard dimensions, for example a 1/4" router bit will be

too wide you will need a 15/64" bit to cut a dado to fit it. MDF machines very well and is often used for moulded components on painted furniture. Its main draw back is that it is a very heavy product compared to real wood. Hardwoods are also commonly used as outer veneers on manufactured sheets. These veneers are extremely thin sheets of wood that are glued to a panel core of plywood or particleboard. Such panels are usually 4'x 8' sheets, but they are available in other sizes, for example Baltic Birch is sold in 5' widths. Their thicknesses range from 1/8 inch to over 1 inch. Because

of their laminated construction, they are extremely stable in all

dimensions. Since the veneers on any given panel are usually cut

sequentially from the same log, the panel should display a uniform

color and grain. Matching the grain pattern of solid wood to the

generally uniform grain pattern on the panels can be difficult. But

careful planning can yield good matches in the most visible areas of

your project. Cutting sheet goods with a circular saw.

|

Related Links |

|

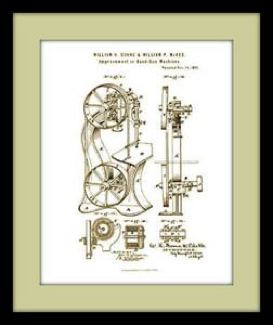

This site sponsored by: Vintage Internet Patent Prints Vintage Internet Patent Prints are reproductions of the actual patent drawings printed on acid free parchment paper. Each drawing is an exact copy of the original showing the inventor, patent number and year of the patent. Large selection to choose from, something for every decor! |