"Helping woodworkers online for over 20 years"

Hand Drills 101

| Electric drills are by far the first power tool purchased, they have so many uses besides drilling holes, there are attachments to turn them into paint mixers, sanders, screwdrivers, saws, grinders, lathes, the list goes on, some work others don't. |

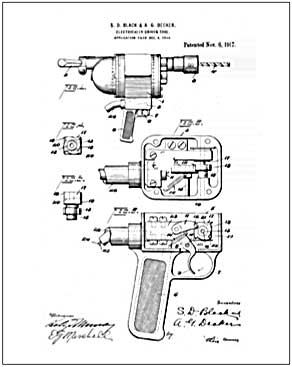

The first hand drill was patented by Fein in 1897.

There are corded and cordless drills, so far each have their place. I would recommend starting with a 3/8" capacity, variable speed, reversible corded drill, it will not be as handy as a cordless but you will get good performance for a low price. Choose a slower speed model, (max. 1200 rpm), they seem to have more torque for drilling larger holes yet still drill clean smaller holes. Most drills are now double insulated which is a safety factor, if it has a three prong plug use a three prong extension cord. |

|

Corded Drills

Corded drills come in many configurations, 3/8" and 1/2" capacities are the most common, this refers to the diameter of the drill shank the chuck will hold. Features include variable speed controls, reversing , and special hammer drills for drilling into rock or concrete. Attachments are available to convert hand drills to drill presses, some of these are quite satisfactory if holes have to be drilled straight. Usually when a drill stops working it is because the brushes have worn down, replacements can be obtained from service depots, some can be changed easily without taking the drill apart.

Cordless Drills Cordless drills are continually improving, as higher voltage batteries are becoming available, a top of the line cordless drill is a very impressive tool, unfortunately there are lower voltage units that are totally inadequate. Because these drills are used so much for driving screws many have an adjustable clutch to regulate the depth that screws are driven in and are now frequently referred to as Driver-Drills. Voltage ranges from 4.8 to 24, speeds are usually around 0 - 700 or 350 - 1200 rpm, many are dual speed offering both ranges. Lower end models have on-board batteries, the more expensive models have battery packs allowing one pack to be charged while using another. There are now families of tools that use common batteries which is something to take into consideration.

Lithium-ion or L-ion batteries are now more common, they are much lighter than the Ni-MH style, and have a much quicker charge time. Chucks Drills will have either a chuck with a key, or a keyless style chuck. Keyed Style

With the key style the bit is tightened into the chuck by inserting the key in a hole in the side of the chuck and turning it until the bit is secure. There are three holes, to securely lock the bit tighten at all three positions. Keyless

With the keyless chuck the bit is secured by rotating part of the chuck with your hand. These work well for smaller style bits, many of the budget models do not work that well for larger sizes.

1. Wear eye protection. |