Drill Press

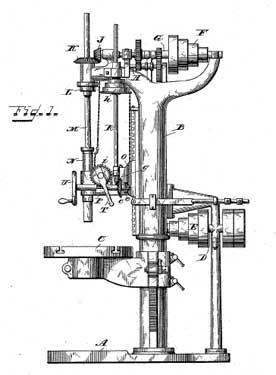

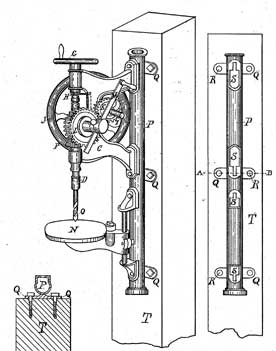

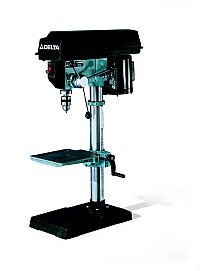

A drill press (also known as pedestal drill, pillar drill, or bench drill) is a fixed style of drill that may be mounted on a stand or bolted to the floor. The main parts are the column, table, spindle, chuck and drill head. The drill head has a set of usually three handles that lower the spindle toward the table. The table can be raised or lowered along the column generally by a rack and pinion mechanism. Early Drill PressesThe first electric drill was patented in Australia in 1889.

Additional Info

|

|

For precision drilling a drill press is pretty well a necessity, a good heavy duty model will have at least a 3/4 HP motor and a 5/8" chuck. Sizing

The size of a drill press is determined by the distance the drill bit is from the column, a 12" drill press would be capable of drilling a hole in the center of a 12" disk. A common misconception is that floor models have a larger capacity than bench tops. There are small bench top models but with the larger sizes the bench tops are equipped with the same drill head as the floor models. Speeds

Speeds are selected by a vari-drive system or the arrangement of belts on stepped pulleys, most have three pulleys and two belts, to deliver a range of 12 or 16 speeds from

|

| 1. Wear eye protection.

2. Run drill at correct cutting speed. 3. Use a vise or clamp for small material. 4. Remove chips with a brush, never by hand. 5. Ease up on pressure as bit breaks through material. 5. Ease up on pressure as bit breaks through material. 6. Don't drill with too much pressure, if the bit is dull sharpen or replace it. 7. If drill binds, shut off machine, turn chuck backwards by hand to free bit. 8. When drilling deep holes withdraw drill to clear chips frequently. 9. Remove drill chuck key immediately after using. 10. Keep floor area around tool clear. |