A good circular saw is a "must have" tool, it will

be used for home improvement or renovations and it is the easiest

way to cut a sheet of plywood down to sizes manageable on a table saw

or bandsaw for your projects. There are many different styles and

models on the market,select a style that feels comfortable, I find

some very heavy, others have an awkward positioned handle. Purchasing

a higher quality model is a good investment, this is a tool that you

will use for a lifetime so you might as well get a good one. Don't go

cheap on the blade it is not worth having tearout on an eighty dollar

sheet of plywood an inch wide on each side of the cut just to save a few

dollars.

|

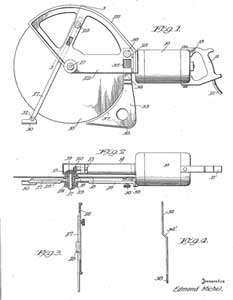

The first practical portable electric circular saw was invented by Edmond Michel and patented in 1924.

He founded the Michel Electric Handsaw Company to manufacture the saw in partnership with Joseph Sullivan.

The company name was later changed to Skilsaw Inc.

Portable circular saws in general are often referred to as Skilsaws or Skil saws. |

Types of Saws

Worm Drive

This style offers better control and accuracy, used mostly by professionals, |

Direct Drive

ThIs is the most common style, available in right and left hand models. Used by both contractors and the home handyman. |

Cordless

With the better life of L-ion batteries this type

of saw is becoming a popular choice. Extremely handy in locations where

power is not available. |

Track Saws

|

With a table saw's

accuracy, a panel saw's capacity, and a circular saw's portability, the

track saw makes precise, splinter-free cuts in almost any situation with

minimal setup.

Simply lay the

zero-clearance 59-inch track on your work-piece and plunge in with the

1,300 watt saw. The track's undermounted friction strips "grab" your

stock - no clamping necessary - while the saw slides smoothly on four

low-friction glide strips.

Available in both corded and cordless models.

Shop and Compare at Amazon.com

|

Saw

Blades

40 Tooth

The more teeth on the blade the smoother the cut. |

16 Tooth

This blade is used for fast cutting of construction grade material. |

Vinyl & Panelling

Cutting thin material requires a fine tooth blade |

Using a

Circular Saw

Always

treat these saws with respect, make sure that you have a firm hold on

the saw and the material being cut. Position the saw on the edge of the

material aligned with the cut mark, start the saw and push it straight

into the material. Be aware of where the cord is, it is easy to saw

through it. Make sure that you will not be sawing into your sawhorse or

bench. Use a sawhorse with a wide top to hold material being cut.

Cut-off Square

This

triangle shaped guide allows it to be held to the board with your left

hand with room for the saw motor to pass. Make the sides of the

triangle about 9" long out of 1/4" thick plywood, the front guide ois a

1" X 3/4" strip about 14" long. Fasten the triangle to the strip with

wood screws with the perpendicular edge of the triangle at right angles

to the top of the strip. Your first cut should cut through the strip

and the end of it is now used as a guide to position the jig.

Cutting Large sheets

Use a Sheet Rack to support the sheet, cut along a straight edge, either make one or purchase a factory made one. Cut on the back side of the sheet with a quality blade for a smoother edge.

1.

Wear eye protection when using the saw.

2. Have firm control of the saw and

material being cut.

3. Make sure the blade is sharp and

suitable for the job at hand.

4. Make sure blade guard is working,

never tie it up out of the way.

5. Check used material for nails or

other foreign objects before cutting.

6. Unplug saw before making

adjustments or changing blade.

7. Do not over-reach, always have firm

footing.

8. Allow saw to reach full RPM before

starting cut.

|