"Helping Woodworkers Online For Over 20 Years"

The glued joint in its various forms is in use in every country in the world, and is frequently met with in mummy cases and other examples of ancient woodwork. Alternative names under which it is known are the butt joint, the rubbed joint, the slipped joint, whilst in certain localities it is known as the slaped (pronounced slayped) joint.

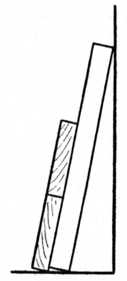

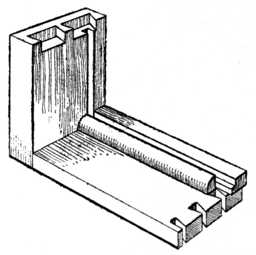

The glued joint is made by planing two pieces of timber so that when placed together they are in contact with each other at every point; they are then usually united with glue. Fig. 1 shows a sketch of a butt joint in its simplest form. In Fig. 2 is indicated the method of holding the joint whilst being glued; the upright portion is held rigid in the bench vice, thus leaving the left hand to hold the piece which is to be jointed, whilst the right hand operates the glue brush. The pieces of wood which form a butt joint may be glued together with or without the aid of cramps or artificial pressure. If the joint is to be made without cramping, the two surfaces of the timber are warmed so as not to chill the glue. The surfaces are then glued and put together and rubbed backwards and forwards so as to get rid of the superfluous glue. They are then put aside to dry.

Glueing.—The better the glue penetrates into the pores of the wood, the stronger the joint will be; for this reason timber of the loose-fibred variety, such as pine, etc., will hold up at the joint better than hardwoods like teak and rosewood. The glue used for jointing should be neither too thick nor too thin; the consistency of cream will be found suitable for most purposes. It should be nice and hot, and be rapidly spread over the surface of the wood.

If light-coloured woods, such as pine, satinwood, sycamore, etc., have to be jointed, a little flake white should be procured and mixed into the liquid glue. This will prevent the glue showing a thin black line on the joint.

Broad surfaces of close-grained hardwood having a shiny surface are usually carefully roughened with a fine toothing plane blade previous to glueing.

Supporting the Joint.—The jointed boards should not be reared up against a "bench leg" or wall without having any support in the centre, as dotted line at Fig. 5, because in all probability they will fracture before the glue has time to set; and, when we go to take them up to renew working operations, we shall be annoyed to find that they have assumed a position similar to that at Fig. 5 (shown exaggerated), and this will, of course, necessitate re-jointing.

Fig. 3.—Correct Jointing. |

Fig. 4.—Faulty Jointing. |

Fig. 5.—Boards unsupported. |

Fig. 6.—Boards supported. |

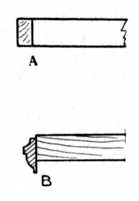

Fig. 7.—(A) Glued Slip, (B) Glued Moulding. |

Fig. 8.—Grain alternating. |

A correct method to adopt is seen at Fig. 6. Here we have supported the joint by rearing up against the wall a couple of pieces of batten, one at each end of the board, thus supporting it throughout its entire width until the glue is thoroughly set. The two or more pieces of timber in a butt joint adhere by crystallisation of the glue and atmospheric pressure. A well-fitted joint made with good quality glue is so strong that, when boards of 3 feet and upwards are jointed together by this method, the timber in most cases will break with the grain sooner than part at the joint.

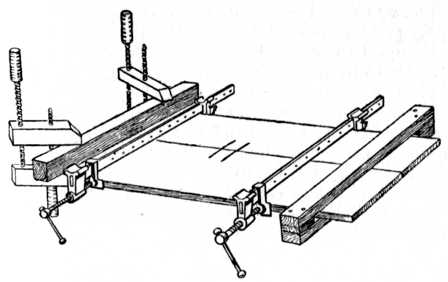

Butt joints may be cramped up, if desired, and it is customary to warm them as previously stated. In the absence of the usual iron cramp, the amateur may make an excellent wooden arrangement out of any odd pieces of timber that happen to be handy. Two blocks of hardwood are screwed on the base board at a suitable distance for the work in hand; the boards to be jointed are glued and placed in position between the blocks; and the two hardwood wedges are inserted and hammered in opposite directions to each other, thus exerting the desired pressure. An example of this method of cramping is shown in Fig. 25, which also indicates the use of iron "dogs."

When jointing, care should be taken to first plane up the boards true on one side—i.e., take them out of winding. The method of testing for this is shown at Fig. 9, and it may with advantage be used when jointing the edges of the boards. Two laths or strips of wood are planed up to exactly the same width, having their edges straight and parallel. One edge of each lath may, if desired, be bevelled a little. The method of using these "twist sticks" or "winding laths" is to put them on the board as indicated, and sight along their top edges. The winding laths, being much longer than the width of the board, show up the irregularity greatly pronounced.

The Tools generally used for making the butt joints are:—

The jack plane, for roughing the edges, etc.

The wooden trying plane (or iron jointing plane) for trueing up the work.

The try square for testing purposes.

The winding laths and straight edge.

The Method of Work is as follows: Each board is in turn put in the vice and planed straight lengthwise; it is then tested with winding laths and a try square (the latter method is shown at Fig. 22).

The boards are then put on the top of one another as at Fig. 1 and tested with a straight edge; they should appear true as shown at Fig. 3; if they show faulty as at Fig. 4 the joints must be again fitted until the required degree of accuracy is obtained. Difficulties may be avoided by care in selecting timber suitable for jointing, and it must be remembered that timber shrinks circumferentially (the heart side becoming curved) as dotted lines in Fig. 10. If the timber be jointed with all the heart side one way as at Fig. 10, the tendency will be for it to cast as shown by the dotted line. If the timber be alternated as at Fig. 11, the tendency will be to cast wavy, whereas if quartered timber can be obtained it will stand practically straight as the tendency to shrink is in thickness only. The grain of quartered timber is shown in Fig. 12.

Fig. 11.—Heart side of Timber shown alternated. |

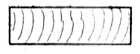

Fig. 12.—Grain of Quartered Timber. |

Judgment should also be exercised to avoid jointing in which one piece of timber is wild and large in the grain, and the adjoining piece of a mild-grained nature. Jointed boards should always be glued up with the grain running in the same direction if possible; this we show at Fig. 13, and nothing looks worse than a dressing chest end or similar piece of work in which the grain runs haphazard. When jointing thin timber (say, 1⁄4-in., 3⁄8-in., 1⁄2-in. and 5⁄8-in. boards) the best method is to use a shooting board (Fig. 26). It must be noted, however, that a shooting board and plane practically never give a true right angle, owing to wear and the grinding of the blade. Therefore, the boards should not all be laid with the "face mark" on the shooting board whilst the edges are shot, because any inequality would be multiplied by the number of pieces jointed. A better method is to alternate the boards, face side up, then face side down, whilst shooting the edges; this will prevent convexity or concavity on the face of the jointed board, because any slight error in the angle is neutralised (see Fig. 8).

Applications of the Joint.—The following show various applications of the butt or glued joint:—

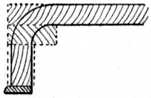

Fig. 7A shows a mahogany or other hardwood slip glued on the edge of a cheaper wood, such as pine or whitewood, as is the case on bookcase shelves when only the front edge is seen and polished.

Fig. 7B shows a moulding glued on a shelf, both mould and shelf in this instance being of polished hardwood. A shelf of this type might be used in a recess, the object of the overhanging moulding being to hide a small 3⁄8-in. iron rod which would carry the curtain rings and heading of the curtain which covers the recess. The shelf would be fixed about 3 ft. 9 ins. to 4 ft. 3 ins. from the floor.

Fig. 14 shows the wing pieces glued on the top bearer of carcase work. The application of this bearer in its position will be shown in the chapter on Dovetailing.

Fig. 15 shows a butt joint planed at an angle of 45 degrees (commonly called a mitre), used for box feet, etc.

Fig. 16 shows jointing up of an ogee-shaped panel. The dotted lines indicate the thickness of the timber previous to its being worked up to the finished shape. Bow-fronted and semicircular panels are jointed in a similar manner.

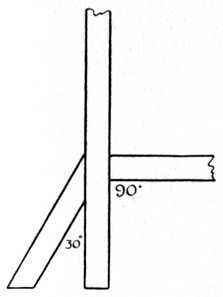

Fig. 17 shows timber jointed at right angles to the upright piece, and at an angle of 30 degrees.

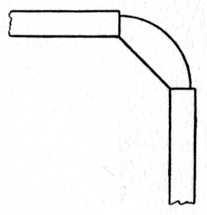

Fig. 18 indicates quarter-circle jointing, as used in round-cornered chests of drawers, wardrobes, cupboards, etc.

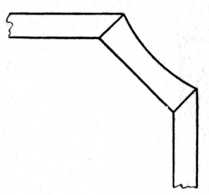

Fig. 19 is similar to Fig. 18, but with hollow (or concave) corners.

Fig. 17.—Jointed Timber at 30° and 90° angles. |

Fig. 18.—Convex Corner. |

Fig. 19.—Concave Corner. |

Fig. 20.—Jointing a shaped Spandrel. |

Fig. 21.—Building up Case of Piano Front. |

Fig. 22.—Use of the Try-square for Testing Edge. |

Fig. 24.—Glueing Ploughslips to Drawer. |

Fig. 25.—Method of holding Glued Joints with Iron Dogs. |

Fig. 20 gives us the jointing up of a shaped spandrel to the required width. In a case of this description suitably grained and coloured wood should be selected, otherwise the bad match will at once draw attention to the joint.

Fig. 21 shows the application of butt or glued jointing to the building up of the core of a piano fall previous to shaping up and veneering.

Fig. 23.—Laminated work—the building up of circular rims for cabinet and joinery work. Plan and elevation show rim pattern of a pulley as used in the pattern-making trade.

Fig. 27.—Cramping Glued Joints: Handscrews and

Batten shown at left; temporary Batten at right to

keep the wood flat.

Fig. 27.—Cramping Glued Joints: Handscrews and

Batten shown at left; temporary Batten at right to

keep the wood flat.

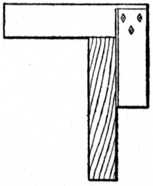

Fig. 24.—The glueing of a ploughslip to a drawer side is seen here, the ploughslip being used to carry the drawer bottom.

Fig. 26 shows the method of jointing with shooting board and trying plane; the right hand operates the plane whilst the left hand holds the wood firm upon the shooting board.

Owing to the importation of narrow and faulty timber the necessity of jointing is greater to-day than ever it was, wide timber of course meaning higher cost for raw material.

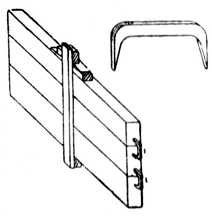

The method of using iron dogs is illustrated in Fig. 25, and it will be observed that owing to the wedge-like formation of each fang (see enlarged sketch) the dog exerts the necessary pressure to close the joint. At the centre of this illustration is suggested the home-made hardwood blocks, baseboard and wedges referred to on page 4.

Fig. 27 shows how the iron sash cramps are used to apply pressure to the joint. As this method is in some cases apt to bend and distort thin boards it is wise practice to fix (as a temporary measure) a stout piece of straight wood on to the board to be joined by using two handscrews as shown at the left hand of the illustration. At the right hand of the sketch a wooden cramping arrangement of the box type is given, and by wedging up the boards are closed together. It is obvious that if this type of box cramp be used it will prevent the boards buckling and the handscrew method at the left may be dispensed with.

| Titebond® Glue | |

| The cabinetmaker's standard. A ready-to-use aliphatic resin adhesive with outstanding strength. We also have Titebond Dark Wood glue for dark woods. |  |