Work Area Shop Lighting

|

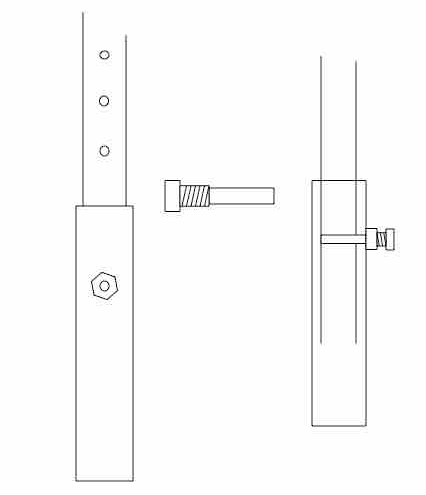

Bottom legs Drill a hole toward the top of the larger tube large enough that a

bolt will pass through, thread a bolt into a nut, insert the bolt into

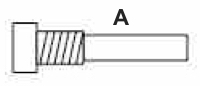

the hole and weld nut in place. Bolt The bolt acts as pin so the top cannot slip down and also locks the two sections of the legs together making the table rigid.   The length of line A determines the length of the

end of the bolt that has to be reduced in size, this can be done in a

lathe or hand filed if necessary, remove enough material so the it will

pass through the nut.

Top Legs

Drill holes in one side of the top legs just

large enough for the bolt stub to pass through, the stub will tighten

against the other side forcing it out against the outer leg.

Additional Notes

All legs must be made identical to each

other, this can be done by lining them up side by side, laying a square

across them and marking the positions to drill.

No measurements have been given as that will depend on the size of the material used, use at least 3/8" bolts or larger.

Lighter tops can the raised or lowered simply doing one end at a time and lifting or lowering the top by hand, heavier tops can be adjusted with a scissor jack under the center of the top. |