Screwdrivers

|

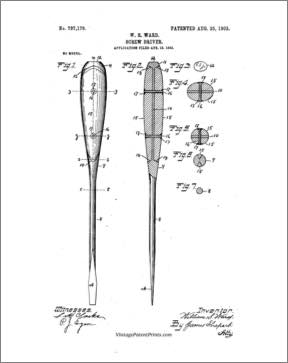

The Perfect Pattern Screwdriver was patented by

|

| Flat Slot

These are a basic item to have in assorted sizes, not as popular as they once were but still necessary. It is very important that the bit be the right size for the slot in the screw otherwise it will probably slip and strip the edges of the slot making the screw nearly impossible to work with. The bit must be kept in good condition by grinding or filling it square as they tend to wear at the outside corners. When purchasing screws for projects be advised to use Phillips or Robertson style screws.

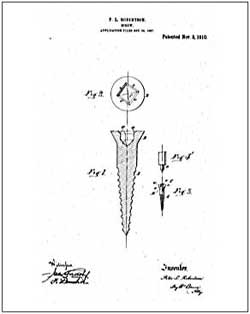

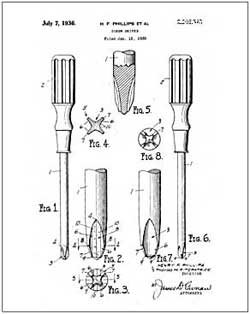

At least the three sizes, #1, #2, and #3 should be in your tool box. This type of screw will sit on the end of the driver as it is started and is less likely to slip as it is being driven.

Often referred to as socket head or square drive, they have been very popular in Canada for years and are becoming more readily available in the U.S.A. The drivers are differentiated by the colours of their handles. Green, red and black are the three most popular. They have all the advantages of Philips plus the fact that they usually will stay on the driver even when pointing downhill. Torx

6 point star shaped Torx screws are commonly found on automobiles, motorcycles, bicycle brake systems (disc brakes), hard disk drives, computer systems and consumer electronics. The sizes are described using a capital T followed by a number, common sizes include T10, T15 and T25.

Screws Pilot Holes There are two basic reasons for drilling pilot holes (1) a tight fit, and (2) material does not split. The pilot hole in the top piece should allow for a snug fit of the screw shank, and allow the threads on the screw to get a good grip without stripping in the bottom piece.

Pilot holes can be drilled with special bits that are made for different size diameter and length of screws and will also countersink the head of the screw. NOTE: Brass screws are very soft and will tend to break, even with pilot holes, before they are driven all the way, to prevent this drive a steel screw the same size and with the same thread pattern first to cut threads in the wood, remove it and drive brass screw. Drywall screws are not suitable for use in

wood to wood situations, they are brittle so do not have the necessary

shear strength. A home inspection may fail if they are used improperly.

Shank & Pilot Hole Guide

Screw Heads Screws come with many different styles of heads, the three most common are flat, round and pan.

These are probably the most common, they are countersunk so they don't protrude above the surface so can be filled and painted over and become invisible. This type of head is used in butt hinges. The heads have an included angle of 82°.

These are used when a countersunk head is not required.

These are similar to round head except the top of the head is flat, self-threading metal screws are a good example. Sizes Screw sizes are listed with the shank size first then the length. Shank sizes are denoted by #'s, the larger the number the larger the shank, the most common sizes are #6, #8 and #10 so a medium size screw 1 1/2" long would be listed as: #8 X 1 1/2". The threads become coarser as the size increases, a #6 screw will have 18 threads per inch, a #8 will have 15, and a #10 will have only 13.

|

|