Keeping It Square 101

There is nothing more fustrating than getting part way through a project and finding things have gone wonky. There are ways to prevent this as you work along, both through measurement and with the use of jigs to keep things in place.

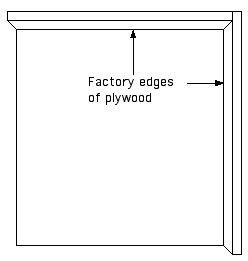

Corner Jigs for Boxes

Squaring a Board To square a board follow these steps: Run board through jointer or hand plane one edge and one face straight. Run board through planer to attain desired thickness, with straight face down. Run board through table saw and cut second edge with guide set aprox. 1/16" wider than finished size of board. Run board through jointer or hand plane second edge to desired width. Cut one end of board square aprox. 1/8" from end. Measure length and cut second end. For panels glue up boards before trimming ends.

To Test a Square Not all squares are created equal, when purchasing a square check it for accuracy, and occasionally afterwards, dropping or banging it against something can throw it out. When checking a framing square check both the inside and outside for accuracy. There is a link here about checking and adjusting squares. Consistant Cuts For an object to be square the opposite sides must be exactly the same length, this is best accomplished if all the cuts are made with the same set up. This is where a cut list can be used to great advantage, for example set the fence on your table saw and make all the cuts with that dimension, then move on to the next dimension on the list.

|