-

Building a Workbench

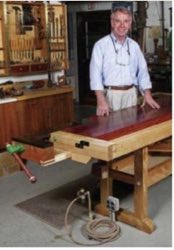

Workbenches

come in many shapes and sizes, many are meticuliously crafted and are

the pride of the shop while others are hastily thrown together out of

necessity.

Woodworking

tutorials often suggest building a workbench as a first project, then

offer plans for masterpieces costing hundreds of dollars and countless

hours to build. This in my opinion is a bit like putting the cart

before the horse, you just may end up with a pricey white elephant

taking up room in your shop. There are many factors that come into play

as to the type of bench that will fill your particular needs, in most

cases it is best to let time dictate the criteria.

How much room do you have? This will help determine the size of bench suitable for your shop.

What

type of tools will you be using? Will you be using mostly hand tools or

powered machiney, if you are using hand tools you will want a good vise

and bench dogs. In shops with power tools workbenches are often built

to do double duty as table saw or planer out-feed tables.

What

kind of work will you be doing? Small projects can be assembled on a

bench that is fastened to a wall, the projects can be turned around on

the bench to work on them. When working on larger projects it is often

an advantage to have the bench in the center of the shop so you can

work on all sides of it.

A

bench top should be flat and solid, the thicker the better, 3/4" is

about the minimum, double or triple that is better. You don't want

tools or your project bouncing around on it when you drive in a nail. A

perfectly flat top is critical for assembly work. A solid core door is

a popular choice by many, often on top of a couple sawhorses in the

beginning.

The top

can be a glued up wood panel or sheet goods such plywood or MDF. It is

quite common to cover the top with a disposable sheet of thin hardboard

to protect it from damage from sharp tools and the effects of stray

bits of glue and stain.

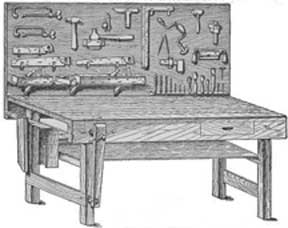

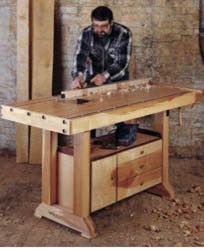

Many

bench tops have tool wells built into them, this is very much a

personal preference as there are both pros and cons about them. Your

tools are out of the way for assembly and you don't have to worry about

banging a finished board against the sharp end of a chisel. On the

other hand they are usually full of shavings and sawdust so you can't

easily find what you are looking for.

Equally

as important as a solid top is a rigid frame to support it. A half-lap

joint in the leg for the vertical stringer is a common method to obtain

maximum support and rigidy. These joints can be cut into material such

as 4X4's or they can be easily made by scabbing 2X4's together.

|

A

simple frame can be made by making two sets of legs as shown. Cut the

long rails to support the top and a shelf 5" shorter than the length of

the top. Cut two short rails to run across the top of each end 2"

shorter than the top to connect the two sets of legs. Cut two plywood

panels to sit below the short rails on the end and fasten them to the

legs, they do not need to be the full height of the bench. |

|

Your

finished frame should be 2" shorter and 2" narrower than the top, this

will allow the top to hang 1" over the frame on all sides. This over

hang will be very handy when it comes time to clamp something to the

bench top.

If your

bench is fastened to a wall only one set of legs will be required, just

fasten the long back stringers to the wall studs.

Dimensions

Space

will be one factor in determining the size of bench to build, but even

if you have lots of room don't make the bench too wide. You don't want

a bench so wide that you can't easily reach across to the other edge,

36" is pretty well the maximum.

Generally the

height is determined by you standing with your arms at your side with

palms facing back, bend your hands up to a horizontal position. The

distance from your palms to the floor is the usual height of the bench.

If you intend to use a lot of hand tools then you may want it a bit

lower, experiment by going through the motions at a kitchen table or at

your table saw and adjust the height to what feels comfortable.

If the

ultimate height is close to your table saw height consider making it to

match the table saw so you can also use it as an out-feed table.

Portability

Portability

of a bench has advantages and disadvantages, the ideal bench is heavy,

this is a good thing when you are working on it, but not when you wish

to move it. Castors can be added to all legs to make it really easy to

move around, however it may also tend to move around while working on

it. Stability can be attained by the use of locking castors, or only

putting castors on one end but this means the heavy other end must be

lifted. The condition of your floor also comes in to consideration, if

it is not flat then the bench will tend to rock because one leg is up

in the air. Always make all four legs the same length and shim under

the short legs rather than building a bench to sit level on an uneven

floor, you may wish to move it in the future.

Vises

Anyone

using hand tools will wish to have a vise or two attached to their

bench. Have your vise on hand before starting on your bench so you can

design it to work with that particular hardware. Idealy you will have one on the the front and one on one end.

-

Bench dogs are pins that go

into holes in the bench top so that a board may be held in position

utilizing a attachment on most workbench vises.

-

-

-

-

-

A

bench is any flat surface in the shop, many of us have cast iron

assembly benches that also double as table saws. Furniture builders

have low benches covered in carpet to assemble cabinets on. Many shops

will have a drawing board attached to a wall, and often a "dirty" bench

with a machinist vise for repairing tools. Having a

dedicated "dirty" bench keeps metal shavings and grease from

contiminating your wood projects, one little metal sliver can destroy a

planer blade, grease stains can ruin a finish.

-

|