Simple Drawer Construction

|

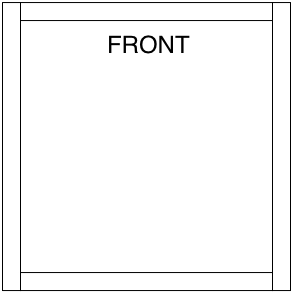

A drawer is

a boxlike storage compartment without a lid, made to

slide horizontally in and out of a desk, chest or

other type of cabinet. Many different joinery methods

may be used to construct the drawer from simple butt

joints to more complicated locking joints

incorporating dovetails or rabbets. The

front of the box must be able to withstand the stress

of pulling on it so it is essential to take this into

consideration when deciding on the type of joint to

use.

|

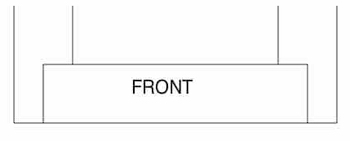

Butt Joint A simple butt

joint is suitable for light use, notice that the sides

extend to the front of the box adding some extra strength

to the unit. Use glue and screws to attach the joints.  Rabbeting

the side boards is a more common practice when making a

butt joint, this may be done at both ends or only on the

front.

With

these methods a separate front has to be attached to cover

the ends of the sides. This may be referred to as a four sided drawer.

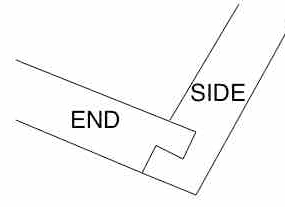

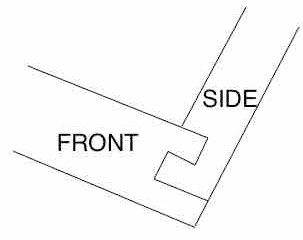

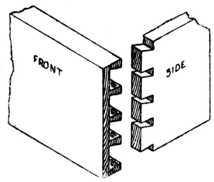

Locking Rabbet Joint A

stronger joint that can be made with basic tools is the

locking rabbet joint, this can be done with a tablesaw

with a dado blade or a router with a straight bit. It is

basically a rabbet cut on the end board and a dado the

rabbet fits into on the side board. Set your machinery to

cut the rabbet and the dado one-half the width of the

boards.

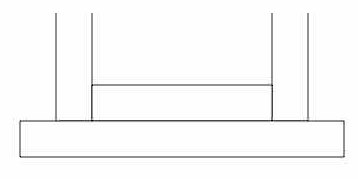

Fastening the BottomA common method is to cut a

dado into all sides of the box at least 1/4" from the

bottom edge, depending on the size of the drawer, just be

aware that the bottom has to be inserted before the joints

are fastened.

Other Methods of Construction

If

you are making several drawers, such as for a complete

kitchen it may be worth your while to invest in a

special bit to make the joints using your router in a

table.

If

you really want to impress people and make a very sturdy

joint then you go to the old standby dovetail joint,

these can be cut by hand or you can make machine joints.

See

our page on hand cutting dovetails.

Before

starting on your drawer decide what kind of hardware you

will be using, this will determine what size to make

your box, this

page on the Rockler site discusses the different

types available and the clearance required.

|