Miter Saws

| A

miter saw will crosscut long stock, cut picture frame molding, fit

crown molding and quickly cut multiple boards to the same length. They

are fast and cut angles with repeatable accuracy. The miter saw has

replaced the radial arm saw in many woodworking shops today.

The diameter of the blade determines the size of the saw, 8", 10", 12" and 14" models are readily available.

Shop Rockler.com

Extending Miter Saw Cut

Up to 24" material can be cut using a sliding model. Make the cut as far as possible (aprox.12"), then unplug the saw. Turn the board over so kerf is facing you, bring blade back and position it in the kerf, clamp material to base, return blade to normal position, plug in the saw and make the second cut. Trimming Just a Hair Sometimes you have to cut a board just a little bit shorter, easiest way to do this is to lower the blade all the way down without turning the saw on, push the board against the blade, hold it in that position, raise the blade and make a cut, about 1/64 to 1/32 of an inch will be removed. Fitting Miters Two important factors come into play getting miters to fit when making boxes or picture frames. 1. The miters must be cut at exactly 45 degrees. A square 90 degree corner can be made with any combination of angles that total 90 but only two 45 degree cuts will make a perfect fit.

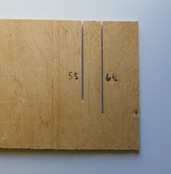

Figure B shows two different angles that form a perfect 90 degree square corner but the edges of the two boards do not line up on the inside. 2. The two opposite sides must be exactly the same length.

The two opposite sides A and B are different lengths, all the angles are perfect 45 degtee cuts, side C has to be tilted in, as shown in red, to meet side A which results in gaps between both A -C and C-D. Note: Line B is shown as an exagerated length to illustrate

the problem.

|